Sous Vide Cooking

Sous vide is a French term for “under vacuum” which is also known as reduced oxygen packaging (ROP). Food is vacuum-sealed and cook in water at a low-temperature; typically, 130–160°F/ 55–71°C. Sous vide cooking can be used for many types of food including meats, poultry, fish and shellfish as well as vegetables, fruits, and even sauces. Because of the low temperature, cooking times can be an hour for tender proteins like chicken breast, or 24-72 hours for tough cuts, like beef brisket. Low temperature cooking, in a low oxygen environment, requires special attention to food safety.

Sous Vide Science

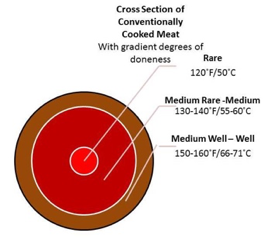

Cooking at low temperatures is a gentle process that is less disruptive to food textures, whether it is meat, fish, or vegetables. Proteins in meats don’t denature and toughen as they would in traditional high-heat cooking methods, so they retain more volume and moisture, resulting in a juicy product with greater yield. Moisture loss and shrinkage can be reduced to as little as 5%, compared to traditional cooking methods of 30% or more. Sous vide cooking doesn’t generate the layered degrees of doneness, like conventional methods, instead creating uniformity from the edge to the center. This is especially important when cooking proteins because it eliminates overcooked or dry edges.

The low temperature cooking, typically between130–160°F/ 55–71°C, when combined with a reduced-oxygen environment, can create pathogen growth if not handled properly. Commercial foodservice operations need to develop a HACCP food safety plan, with multiple barriers against the growth of potentially deadly organisms. Any food designated as TCS (temperature control for safety), including meats and poultry, needs to be pasteurized when cooked at lower temperatures, to ensure they are safe to eat.

When cooking by conventional methods, chicken is typically heated to 165°F/74°C, which instantly kills 99% of active pathogens like salmonella. But with the lower temperatures of sous vide cooking, food must stay in that zone longer as a pasteurization step. See pasteurization chart for safe food handling temperatures for meats and chicken.

Sous Vide Equipment

Anova Precision Cooker

Polyscience Thermal Circulator

Different equipment options for sous vide cooking include an immersion circulator (or thermal circulator), basically a heated water pump inserted into a tank, to maintain a steady temperature; a PID- (proportional-integrative-derivative) controlled water bath with a self-contained heating element; and hand-held versions, resembling a baton with less heating capacity. Some combi-ovens (convection-steam ovens) have sous vide settings. You can also cook sous vide with a crock pot or rice cooker, with the use of an instant-read thermometer.

Sous Vide Packaging

The term “sous vide” refers to the vacuum packaging, or the ROP process, of sealing foods. Use food grade quality bags made of high-density polyethylene, low-density polyethylene, or polypropylene. Heavy duty zip-lock freezer bags also can be used in sous vide cooking but be sure they are made of material that is free from bisphenol A (BPA), known to promote the growth of prostate cancer when heated. (Zip-lock bags should not be used above 158 °F/70 °C because the seams can fail.)

Vacuum Sealers

Vacuum sealers are equipped with manual settings, calculated in millibars (mbar), to control the amount of air that is removed from the bags. The general setting for most foods should be from 30–50 mbar. It’s important to note that the lower the mbar number, the lower the oxygen level. So, at 50 mbar, about 95% of the oxygen is removed, while at 5 mbar, 99.5% of it has been removed. This is important, because too much pressure can crush delicate foods, including fish and shellfish.

When properly sealed, the package will cling to the product, with no visible air pockets. When a vacuum is created, it removes oxygen and moisture, which can dry and damage delicate foods. Decreased air pressure also causes liquids to boil at lower temperatures, so keep foods as cold as possible, to ensure safe food handling standards and minimal damage to the product.

Vacuum Packaging Benefits

Vacuum packaging extends the shelf life of foods, and provides a layer of protection when cooling or freezing. It’s a fast way to marinade or brine foods, requiring less liquid than traditional methods. It also reduces enzymatic browning in fruits and vegetables, like apples and artichokes. Vacuum packaging can be used to compress fruits and vegetables, creating dense and meaty textures, and it has the ability to infuse additional flavorings, like herbs and spices, into them too. It is beneficial for forming and shaping food items, because the vacuum seal wraps the packaging tightly around the product. If used in a safe and sanitary environment, it can also reduce and prevent food-borne pathogens.

Tomato Confit with Basil & Olive Oil, Balsamic vinegar, Salt & Pepper

Poach at 140°F/60°C

for 45 minutes

Compressed Melon

Vacuum sealing creates a textural change without the need of heat

Pickled Vegetables

Equal parts vinegar & water

Add sugar & salt to taste

Alternative Sealing Methods

Water Displacement Method

For sealing bags without a vacuum packaging machine

Immerse a zip lock bag in water to force air out before sealing

Although vacuum sealing the bag is preferred, by immersing a zip-lock bag in water, it displaces the air, forcing it out through the top of the bag. Sealed canning jars are another option.

Sous Vide Mise en Place

No matter the item, sous vide requires typical mise en place, including fabricating, portioning, seasoning, and pre-cooking. Meats and poultry are often seared to enhance color and flavor, since no Maillard browning is created during the sous vide process.

Taste and Seasoning Adjustments

Brined & Seared Chicken

with Fresh Herbs

To prevent bitter spots on foods, wrap fresh herbs in a tea bag, or mix with oil to provide a protective barrier

The sealed environment of vacuum packaging locks everything in, so use less seasoning, including herbs, spices, and flavorings. Herbs and spices can be overpowering, and even bitter, if not carefully adjusted. Wrap fresh herbs in a tea bag, or mix with a neutral oil to keep them from clinging to foods where they can create bitter surface spots. Cook aromatics like onions, shallots, and garlic to mellow their flavor. Heat wine and other spirits to cook-off and evaporate some of the alcohol. Extra virgin olive oil produces a metallic taste in sous vide cooking, so neutral oils (grape seed or canola) are recommended.

Salting of foods, when cooking under four hours is okay, but for prolonged cooking, salt should be added after the cooking process. That’s because the salt draws moisture out, denatures the proteins, and creates a dry texture similar to curing. However, brining adds moisture, and in this case salt is okay to use. Use less brine or marinade because it penetrates deeper under a vacuum. Use smoking, searing, or blanching techniques for proteins and vegetables. Searing is often done after the sous vide process, because it adds texture to the product. Smoking can be done before or after the sous vide step.

Vacuum Packaging Tips

- Always reduce seasoning when cooking sous vide because there is no evaporation

- Vacuum packaging is an efficient way to brine or marinate foods because you need less

- Always lay the product flat when sealing, for efficient cooking, and rapid chilling and freezing

The Cooking Process

Cooking temperatures are usually no higher than the final serving temperature. For meats, poultry, and seafood, sous vide works most efficiently for individual portion cuts, or cuts no thicker than 3”/8 cm, so foods reach their core temperature within four hours. Cooking times vary between 7-40 minutes for delicate fish and shellfish, to one hour for tender meat cuts and vegetables, and 12-72 hours for medium-to-tough meat cuts. Tender or delicate foods (eggs, fish, shellfish, chicken breast, beef, pork tenderloin, and lamb chops) are cooked to serving temperature; tougher cuts must be cooked for extended times for proper tenderization. Use the slow-cooking technique, by setting the water bath 1–2 degrees higher than the desired core serving temperature; or the fast-cooking technique, at higher temperatures to speed the process. Always test times and temperatures yourself, sous vide can produce very soft and mushy textures when left too long in the water bath.

Cooking times for tender cuts of meat, poultry, fish, and shellfish can also be calculated based on the dimensions of the product. However, foods do vary in shapes, so recipe test for a consistent result.