Chocolate - Melting and Tempering

Chocolate is a complex mix of cocoa solids, cocoa butter, along with sugar, and other additives including lecithin and vanilla that is temperature and humidity sensitive. A small amount of moisture, even from steam can affect the chocolate, causing it to seize and become grainy.

Melting Chocolate in a Double Boiler

Liquids like cream can be added to chocolates at higher levels, usually with a ratio of 4 parts chocolate to 1-2 parts liquid by weight, for the creation of sauces and ganache. Because cocoa butter melts between 93-101°F/34-38°C, it separates from the cocoa particles and fats, much like melted butter separates into fats and milk proteins. If the chocolate gets too hot it becomes grainy.

Chocolate for baking merely needs proper melting to be used in a buttercream or cake batter. But if the chocolate is used for piping or enrobing it must be tempered so that it hardens with a clean and shiny finish.

Melting Chocolate

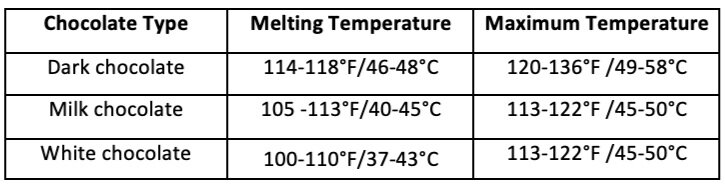

Chocolate used for baking can be melted in a hot water bath or by placing in a microwave oven at 30 second intervals. It can also be melted by placing in a heated warming box set to the desired melting point. The melting temperatures of chocolate varies depends on the type of chocolate and where is grown.

Tempering Chocolate

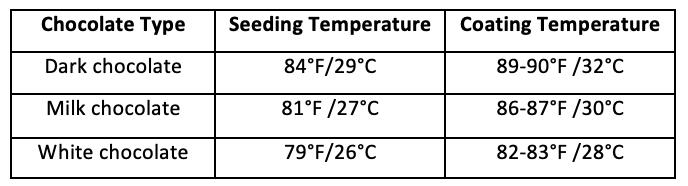

The cocoa butter in chocolate contain various types of crystals that separate when melted. Chocolate used for coating must be tempered by seeding it with tempered chocolate and while stirring it to while lowering and then raising the temperature. A digital thermometer is needed to accurately track the chocolate temperature.

The seeding chocolate can be chopped or in large chunks, which makes it easier to remove once the chocolate has reached a proper temperature. Use a general ratio of 2 parts melted chocolate to 1 part seeding chocolate. Stable crystals in the seeding chocolate encourage stabilized crystal formation in the melted chocolate. Stirring is very important here, because it ensures smaller crystals will form and stay in suspension. Commercial tempering machines are incorporated when producing large batches of chocolate.

Method

Step 1

Assemble all tools for melting, tempering, and enrobing, including a digital thermometer and a rubber spatula

Use at least 2 lb./900 g of melting chocolate

Chop the chocolate or use pre-formed disks and place in a bowl

Melt using the desired method to the proper temperature depending on the type of chocolate (see chart)

Step 2

Add the seeding chocolate and gently stir the chocolate with a rubber spatula but avoid over agitating it which will trap air bubbles

Continue to stir until it reaches the desired temperature

Step 3

Heat the chocolate to the desired enrobing temperature (see chart)

To test the chocolate, spread a small amount on a piece of parchment and cool to room temperature 65-70°F/20-21°C; tempered chocolate will harden quickly (3- 5 minutes) and become firm and shiny

Maintain the temperature of the chocolate throughout the enrobing process